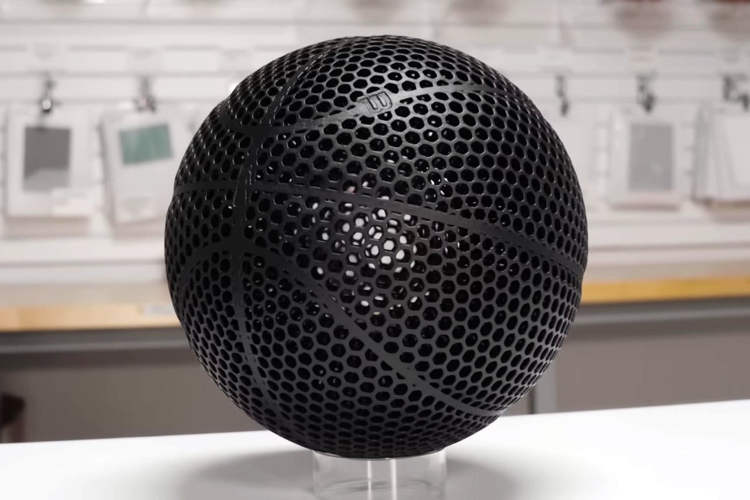

Sports equipment giant Wilson recently unveiled a 3D-printed basketball prototype that does not need to be inflated and features a see-through lattice design.

Basketball technology has come a long way since the early days of the sport when real stitched leather was used as the main material, but Wilson is trying to change the game completely with an intriguing concept that completely does away with pneumatic pressure.

Instead, the Wilson Airless Prototype relies on the elasticity of its “research-grade” polymer material to produce the same bounce as traditional basketballs.

This eliminates the need to inflate the ball to a certain pressure, as well as known problems like puncture risks, and air escaping through the inflation valve over long periods of time

One of the most intriguing features of the airless basketball is the lattice design. Although Wilson has kept the traditional binding pattern of the regular basketball, ensuring that players can still get their fingers into the seam lines for better grip, the prototype has a very futuristic look. Because containing air pressure inside is no longer a requirement, the ball itself is see-through, with hundreds of small hexagonal holes allowing air to pass through.

Working with manufacturing company EOS, Wilson reportedly 3D-printed its airless prototype using the selective laser sintering (SLS) method of additive manufacturing to fuse several layers of polymer powder. The main concern was replicating the bounce of a traditional basketball, which was no small feat, considering there was no internal air pressure to generate rebound.

The Wilson Airless Prototype was unveiled last month, during the NBA All-Star Weekend, when Houston Rockets forward “KJ” Martin was filmed bouncing it around a bit and throwing it at the basket. The heavily-edited video makes it look like a perfectly good alternative to a regular basketball, but the company acknowledges that it is still a prototype that requires more testing.

[Source: Oddity]